With the rapid development of machining industry in our country, the ball valve assembly machine is more and more widely used. In particular, CNC lathes, as a kind of ball valve assembly machine, have been widely used. So how to diagnose and repair the ball valve assembly machine circuit?

CNC lathe adopts advanced CNC technology and mechatronics technology, has high processing accuracy and processing efficiency, and is suitable for the high precision and high efficiency requirements of modern machining industry. However, due to the high degree of automation and complex structure of CNC lathes, the failure rate is also higher than that of ordinary lathes, and the maintenance difficulty is also larger, and the quality requirements of CNC lathes maintenance personnel are also getting higher and higher, and the machine tool is required to be eliminated as soon as possible after the failure.

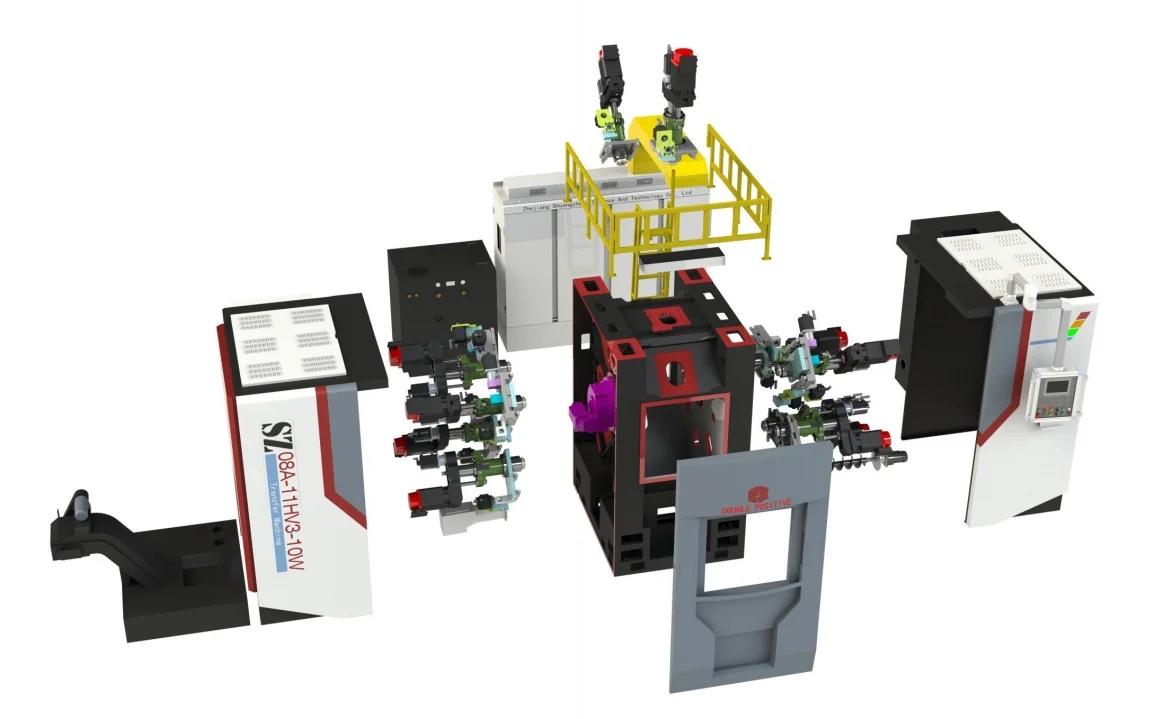

With the continuous development of automation, the use of ball valve assembly machine is also more and more extensive, because the ball valve assembly machine integrates machine, electricity and instrument in the process of operation, Parts are always inevitable to have different types and degrees of faults, so it is of great significance to be familiar with fault characteristics and master the common means and methods of ball valve assembly machine diagnosis.

First, principle: ball valve assembly machine electrical fault maintenance principles

ball valve assembly machine system is diverse and diverse, each machine tool structure, system signals, parameters and software and hardware are specific, but the control principle of the machine tool is similar, so the author believes that the equipment should work principle, Common and special faults such as control systems are summarized and their special places are summarized, and these rules are used to quickly find faults.

Second, analysis: first analysis and then action

I think when we arrive at the scene of the failure, do not immediately start. Instead, ask the operations staff how the failure occurred and what phenomena accompanied it. To find useful information from the operator's narrative, after thinking, analyze the cause of the failure and the location of the failure. And then we can do our own analysis and troubleshooting.

The maintenance of the machine tool is to maintain the machine tool in a good technical state, extend the service life, reduce maintenance costs, reduce product costs, ensure product quality, improve production efficiency must be carried out daily work.

Third, operation: the maintenance of the machine tool should be done

1 Neat tools, workpieces, accessories are placed neatly and reasonably, machine parts and safety protection devices are complete, and various lines and pipelines are complete.

2 Clean the machine inside and outside clean, no dust, no yellow robe, no black dirt, no rust, to the guide rail surface, lead screw, rack, gear and other places to remove oil, no water leakage, no leakage point, chip garbage clean.

3 Lubricated timely refueling, oil change, oil quality meets the requirements; Oil pot, oil cup, oil nozzle complete, oil felt, oil line clean, oil label bright, oil circuit smooth.

4 Safe familiar with the structure of the machine tool and comply with the operating procedures, careful maintenance, reasonable use; All kinds of safety protection devices are complete and reliable, the control system is normal, well grounded, and there is no accident potential.

ball valve assembly machine https://www.zjshuangzheng.com/Rotary-Table-Intelligent-Assembly-Machine.html